Our mission since we began in 1954To forge a trusted relationship built on the best solutions to fit your individual air movement needs.

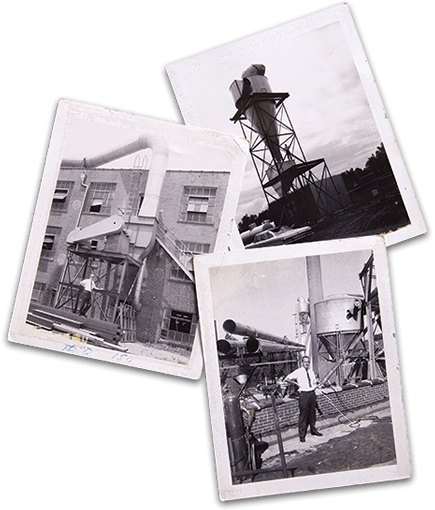

We started in 1954 as a small sheet metal shop. Back then, we mainly serviced the giants of the furniture and wood manufacturing industries. Today, those seemingly invincible customers are all but gone. And yet, we remain.

Built to Last.

Like our products, our business is built for the long term. We have grown into a major supplier of the design, fabrication, installation and service of industrial dust collection systems throughout North America. The key has been a reputation for unrivaled expertise, workmanship, products, customized solutions and, most importantly, service.

Continued Growth.

While dust collection and control is an integral part of our business, it’s not the only part. If your industry produces dust and waste materials from your manufacturing processes, we have a system application to help. The Koger Air brand of systems can be classified as pneumatic and material conveying systems and includes dust collection and control, industrial ventilation, air filtration, fume exhaust, process materials management, and piping systems for biomass, bioenergy, thermal and catalytic oxidation applications.

Standards of Customization.

As the industry has grown and evolved, so have we. In addition to our standard products, we also offer you a custom metal fabrication division to create industry-specific products for specialized manufacturing processes. In fact, companies in our own field often outsource their heavy-duty industrial and stainless steel fabrication products to us.

Value-Added Services.

To complement our contract system business, we also offer value-added products and services, including the Koger line of standard and custom industrial sheet metal components, fans, airlocks and cyclones, as well as the fabrication of customized industrial products.

Service Above All.

We are committed to offering the best solutions available. Above all, we are about meeting both standard and special fabricated product requirements, and each customer can count on getting orders on or before scheduled delivery dates. Standard components are stocked and ready to ship, and custom products are assembled and shipped to beat or meet deadlines. All you have to do is let us know what we can build for you.

Here’s to the Future.

It’s been our honor to service our customers, new and old, and we look forward to the challenges and opportunities the future will bring.

Testimonials

Facilities

Convenient Solutions.

Koger Air Corporation offers 100,000 square feet of manufacturing and warehousing space in Martinsville, Virginia and is centrally located between Roanoke, Virginia and Greensboro, North Carolina to serve you and customers nationwide.

Our facilities include three separate manufacturing plants and a warehouse and service center:

Industrial Pneumatic/Material Conveying Systems and Custom Metal Fabrication

- 21,000 square feet

- Two 5-ton Overhead Cranes

- CNC Plasma Arc Cutting System

- State-of-the-Art Metal Forming and Fabricating Machinery

- 175-ton press brake

- 320-ton press brake

Fan and Airlock Manufacturing

- 24,100 square feet

- Nine work cells

- 5-ton Overhead Crane

- CNC Plasma Arc Cutting System

- Metal Forming and Fabricating Machinery

- Fan balancing

- Machine Shop

Industrial Sheet Metal Component Parts

- 23,920 square feet

- Five angle rolling machines

- Two elbow-forming machines

- Cast Aluminum Production

Warehousing and Service Center

- 26,400 square feet

- Stocked shelves of standard industrial sheet metal components and standard material handling equipment for immediate factory direct shipment

- CNC 500-ton punch press